商铺名称:济南银箭焊接材料有限公司

联系人:马经理(先生)

联系手机:

固定电话:

企业邮箱:mingquanhc@163.com

联系地址:山东省济南市历下区五金市场8号

邮编:250002

联系我时,请说是在焊材网上看到的,谢谢!

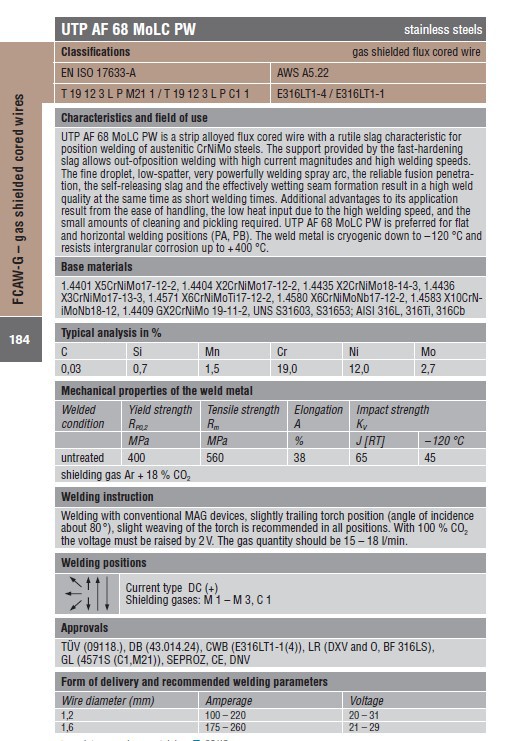

UTP AF 68 MoLC PW stainless steels

Classifications gas shielded flux cored wire

EN ISO 17633-A AWS A5.22

T 19 12 3 L P M21 1 / T 19 12 3 L P C1 1 E316LT1-4 / E316LT1-1

Characteristics and field of use

UTP AF 68 MoLC PW is a strip alloyed flux cored wire with a rutile slag characteristic for

position welding of austenitic CrNiMo steels. The support provided by the fast-hardening

slag allows out-ofposition welding with high current magnitudes and high welding speeds.

The fine droplet, low-spatter, very powerfully welding spray arc, the reliable fusion penetration,

the self-releasing slag and the effectively wetting seam formation result in a high weld

quality at the same time as short welding times. Additional advantages to its application

result from the ease of handling, the low heat input due to the high welding speed, and the

small amounts of cleaning and pickling required. UTP AF 68 MoLC PW is preferred for flat

and horizontal welding positions (PA, PB). The weld metal is cryogenic down to – 120 °C and

resists intergranular corrosion up to + 400 °C.

Base materials

1.4401 X5CrNiMo17-12-2, 1.4404 X2CrNiMo17-12-2, 1.4435 X2CrNiMo18-14-3, 1.4436

X3CrNiMo17-13-3, 1.4571 X6CrNiMoTi17-12-2, 1.4580 X6CrNiMoNb17-12-2, 1.4583 X10CrNiMoNb18-

12, 1.4409 GX2CrNiMo 19-11-2, UNS S31603, S31653; AISI 316L, 316Ti, 316Cb

Typical analysis in %

C Si Mn Cr Ni Mo

0,03 0,7 1,5 19,0 12,0 2,7

Mechanical properties of the weld metal

Welded

condition

Yield strength

RP0,2

Tensile strength

Rm

Elongation

A

Impact strength

KV

MPa MPa % J [RT] – 120 °C

untreated 400 560 38 65 45

shielding gas Ar + 18 % CO2

Welding instruction

Welding with conventional MAG devices, slightly trailing torch position (angle of incidence

about 80 °), slight weaving of the torch is recommended in all positions. With 100 % CO2

the voltage must be raised by 2 V. The gas quantity should be 15 – 18 l/min.

Welding positions

Current type DC (+)

Shielding gases: M 1 – M 3, C 1

Approvals

TÜV (09118.), DB (43.014.24), CWB (E316LT1-1(4)), LR (DXV and O, BF 316LS),

GL (4571S (C1,M21)), SEPROZ, CE, DNV

Form of delivery and recommended welding parameters

Wire diameter (mm) Amperage Voltage

1,2 100 – 220 20 – 31

1,6 175 – 260 21 – 29